What’s wrong

with these fittings?

|

| weird again. |

My fitting

orientation is all wrong. You will get

this especially on zero dead leg valves for pharmaceutical products but I’ve

seen this on other products.

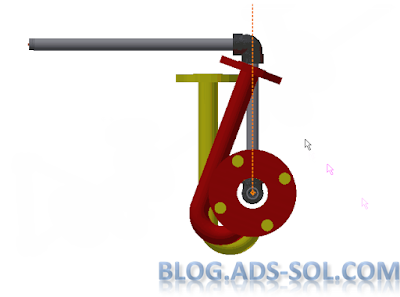

If you create a

plane between the 3 connection points of the valve you will see that it’s not

parallel with the rest of the geometry, valve body in my case.

|

| default orientation |

The direction is

given by the 3’rd connection perpendicular to the line between the first and

second. I think this is to help out with inexperienced users, idiot proof

really, helping out if you didn’t align your connections to the model but that's just for straight fittings like tees.

Now what? Am I supposed to measure the angle every time and

change fitting orientation on a continuous loop? (rolling eyes).

In order to fix this you need to

add another authoring point and make it a 4 point connection.

4 Connections on

a 3 point fitting? Are you mad?

I thought we already

established that and we’re here to have some fun and solve some problems.

We will be creating the 3rd connection inline

(same plane) and parallel with the fitting as spare, never to be used and

instead the 4th connection is to be used.

It might help to

make the 3rd on a different plane away from 4th like right on the origin line

just so it’s out of the way when placing or connecting fittings to it. We want

to make it very obvious from the snap preview that it’s not the one to be used.

|

| authoring dialog window |

I have also gave

it a really small connection size; a size we would never use like 1/8” to differentiate

it even more and keep people from connecting to it.

And this is what

the difference between placing a 3 or 4 connection fitting looks like

I’ve given this

example before on autodesk forum on a similar issue.

You can keep

just 3 connections if you align the third but we can do better.

|

| 3 would do but 4 is better |

I feel it’s best

to have a 4’th connection but be careful on placing fittings.

|

| Watch out for ghost connection when placing this fitting. |

Later,

ADS